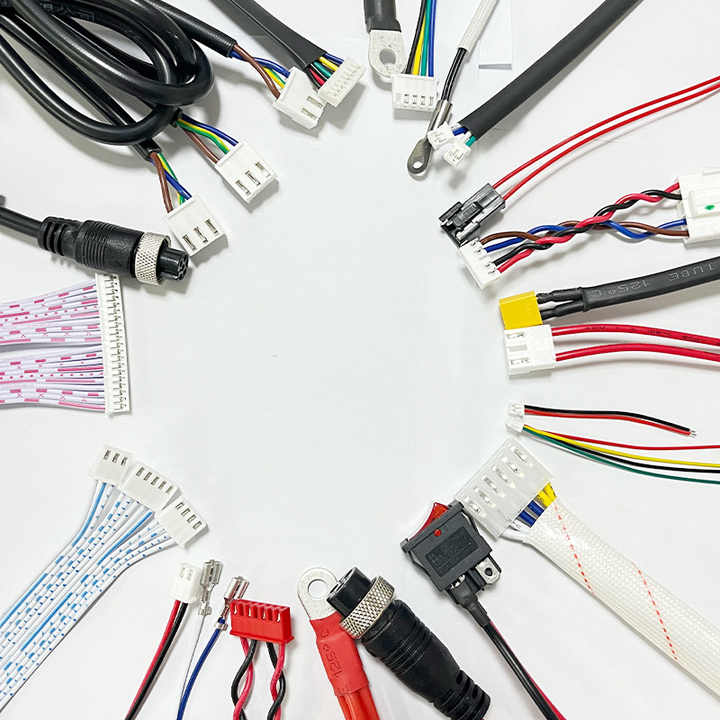

How to choose terminals for your wire harness and cable assembly

Harness Connector Terminals: OEM Imported vs. Domestic Alternatives – A Deep Dive with Case Studies

In the global market for harness connector terminals, the debate between imported OEM parts and domestic alternatives continues to intensify. This article presents a comprehensive comparison, supported by real-world case studies and test data, to demonstrate that high-quality domestic alternatives are increasingly viable options. We’ll explore certifications, quality assurance, cost-effectiveness, and technological advancements to help businesses make informed decisions.

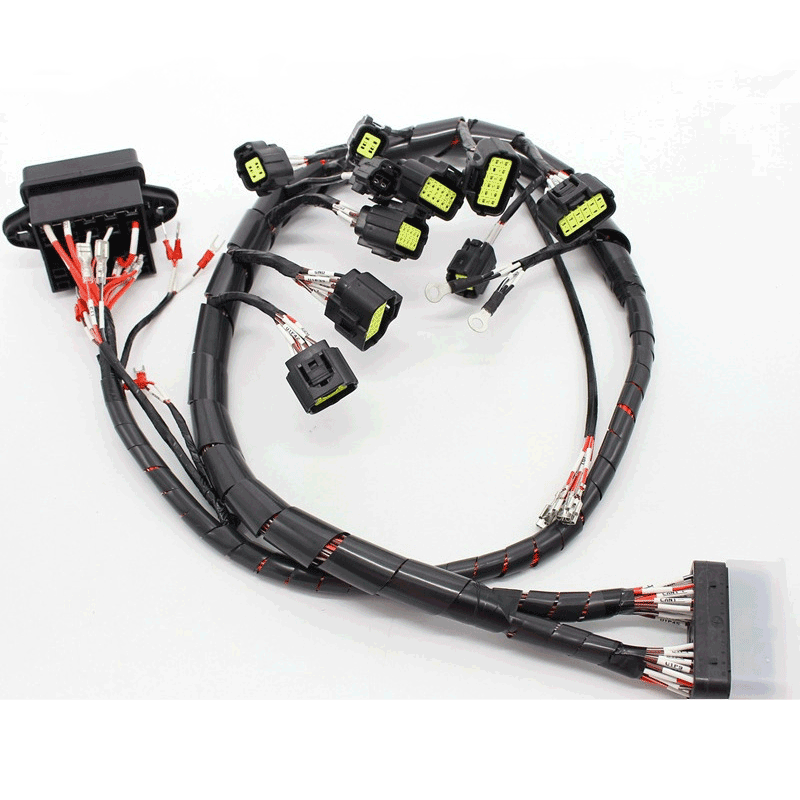

Understanding Harness Connector Terminals

Harness connector terminals are metal components used to establish secure electrical connections within wire harnesses. They are essential for transmitting signals and power in vehicles, industrial machinery, and consumer electronics. The quality of these terminals directly impacts the durability, safety, and performance of the final product.

Advantages of Imported OEM Terminals

Superior Quality and Reliability

Precision Engineering: OEM parts (e.g., TE Connectivity, Molex, JST) are manufactured to strict international standards, ensuring consistent performance.

Material Quality: High-grade metals (e.g., phosphor bronze, beryllium copper) are used, offering better conductivity and corrosion resistance.

Longevity: OEM terminals often have a longer lifespan due to rigorous testing.

Brand Reputation and Compliance

Trusted Brands: Well-known manufacturers (e.g., Amphenol, Delphi) have established reputations, reducing the risk of failure.

Certifications: Many OEM parts comply with ISO, UL, and RoHS standards, making them ideal for regulated industries.

Technical Support and Documentation

OEM suppliers provide detailed technical specifications, datasheets, and application support, simplifying integration.

Disadvantages of Imported OEM Terminals

Higher Cost: Imported parts are 30-50% more expensive than domestic alternatives due to tariffs, logistics, and brand premiums.

Longer Lead Times: Shipping delays and customs clearance can extend procurement cycles.

Limited Customization: Some OEMs may not offer tailored solutions for niche applications.

Certification Standards: Domestic vs. Imported Terminals

International Certifications Achieved by Domestic Brands

Many Chinese manufacturers now comply with strict international standards, including:

UL 1977 (Connectors) – Covers signal and power transmission in industrial applications.

UL 1059 (Terminal Blocks) – Ensures durability in wiring connections.

ISO 19642 (Automotive Wire Harness) – Validates performance in harsh environments10.

Case Study: Automotive High-Voltage Terminals

BYD’s Domestic Terminals: Used in electric vehicles, these terminals passed UL 2580 (EV battery safety) and 720-hour salt spray tests, matching TE Connectivity’s AMP series in reliability.

Cost Advantage: Domestic certifications reduce testing costs by 30% compared to overseas labs.

Military-Grade Applications

Aerospace Example: A Chinese supplier for COMAC’s C919 aircraft developed terminals meeting MIL-DTL-5015 (military connector standards), replacing imports in non-critical systems

Quality Assurance: Test Data and Real-World Performance

Material and Process Improvements

Plating Thickness: Domestic gold plating now reaches 2.5μm (vs. 0.8μm in early iterations), reducing oxidation risks in medical devices.

Smart Inspection: Fiber-optic scanning detects 70% more defects than manual sampling.

Case Study: Automotive Wire Harness Failures

Problem: A domestic truck model faced 43% terminal withdrawal in chassis harnesses due to poor crimping.

Solution: Adopting double-lock terminals (inspired by TE’s design) cut failure rates to 0.3%.

Reliability in Harsh Environments

Vibration Resistance: Domestic FFC (Flexible Flat Cable) terminals in Geely’s A7 model reduced space usage by 80% while passing ISO 19642 vibration tests.

Temperature Cycling: A domestic EV battery terminal survived -40°C to 105°C cycles, matching Molex’s performance

Cost-Effectiveness: Hard Numbers

Price Comparison

| Terminal Type | Imported OEM Price | Domestic Price | Savings |

| High-Voltage (EV) | ¥15-25/pcs | ¥6-12/pcs | 40-60% |

| Low-Voltage (Consumer) | ¥0.5-1.5/pcs | ¥0.2-0.8/pcs | 50-70% |

Supply Chain Efficiency

Lead Time: Domestic orders ship in 2-4 weeks vs. 8-12 weeks for imports.

Logistics Savings: No tariffs or long-distance shipping costs

Technological Innovations in Domestic Terminals

Breakthrough Designs

Piercing Terminals: Jinhu Automotive's patent eliminates wire stripping, cutting installation time by 40%.

FFC Technology: Geely and TE’s co-developed flat cables reduce assembly errors by 50%.

Smart Manufacturing

AI-Optimized Layouts: Machine learning shortens harness lengths by 15% in EVs.

Automated Lines: Domestic factories achieve 99.5% yield rates (vs. 98% for imports)

Conclusion: When to Choose Domestic Alternatives

Best for Cost-Sensitive Projects: Consumer electronics, low-voltage applications.

Hybrid Approach: Use OEM for safety-critical systems (e.g., airbags) and domestic for non-critical sections.

Future Outlook: By 2030, domestic terminals are expected to capture 40% of the global EV market.

Final Recommendation

Verify Certifications: Check for UL, ISO, or RoHS compliance.

Request Samples: Test durability in real-world conditions.

Leverage Local Support: Take advantage of faster customization and troubleshooting.

With improved quality, lower costs, and innovative designs, domestic harness connector terminals are now a smart alternative to imported OEM parts.