How to design and develop automotive wiring harnesses

Classification of car wires

American Standard Automotive Wires (SAE J1128, J1939, etc.)

-

Governing Body: SAE (Society of Automotive Engineers)

-

Common Types: GPT, GXL, TXL, SXL

-

Features:

-

Rated for 60–125°C, depending on insulation type

-

Insulation is typically made of PVC or cross-linked polyethylene

-

Conductor size in AWG (American Wire Gauge)

-

Widely used in North America

-

Applications: General wiring (GPT), high-temp areas (GXL, TXL), and commercial vehicles (SXL).

German Standard Automotive Wires (DIN/ISO standards, LV 112)

-

Governing Body: DIN, ISO, and OEM-specific standards (e.g., VW, BMW)

-

Common Types: FLRY-A, FLRY-B, FLY, FKS, etc.

-

Features:

-

Thin-wall PVC insulation, space-saving

-

Temperature rating usually 105–125°C

-

Metric wire sizes (e.g., 0.5 mm², 1.0 mm²)

-

Excellent flame resistance and flexibility

-

LV 112 specifies performance for modern car networks

-

Applications: Widely used in European cars for body, engine, and CAN/LIN networks.

Japanese Standard Automotive Wires (JASO/DENSO standards)

-

Governing Body: JASO (Japanese Automotive Standards Organization), DENSO, etc.

-

Common Types: AV, AVS, AVSS, CAVUS

-

Features:

-

Very thin-wall insulation (especially AVSS)

-

Temperature rating ~85–120°C

-

Metric sizes (e.g., 0.3 mm², 0.5 mm²)

-

Lightweight, compact for space-constrained Japanese vehicles

-

Applications: Common in Japanese vehicles for dashboards, ECUs, and tight routing.

Selection Tips:

-

Match the OEM standard if replacing parts in a specific brand (e.g., use FLRY in BMW).

-

Consider temperature, voltage, chemical exposure, and space constraints.

-

Choose SAE for North America, DIN/ISO for European cars, and JASO for Japanese vehicles

How to choose the right car wires

Determine the Application Environment

-

Engine bay: High temp (up to 125–150°C), oil/fuel resistant → use GXL, TXL, FLRY-B, or cross-linked wires

-

Cabin/interior: Lower temp, less stress → GPT, AV, AVS

-

Chassis/underbody: Exposure to water, abrasion → use shielded or reinforced insulation

Choose the Correct Wire Standard

-

SAE (e.g., GXL, SXL, TXL): Ideal for North American vehicles

-

DIN/ISO (e.g., FLRY, FLY): Common in European vehicles

-

JASO (e.g., AVSS, CAVUS): Suited for Japanese vehicles

Use the same standard as the vehicle manufacturer to ensure compatibility and safety.

Select Proper Insulation Material

-

PVC (e.g., GPT, FLRY-A): Cost-effective, general use, up to ~105°C

-

Cross-linked Polyethylene (e.g., GXL, TXL): Higher temp (125–150°C), better chemical resistance

-

Silicone or Teflon: Extreme temp or high flexibility needs (less common in standard cars)

Calculate Current Load and Choose Wire Gauge

-

Match wire gauge (AWG or mm²) to the current draw:

-

E.g., 0.5 mm² or 20 AWG for small signals

-

4 mm² or 12 AWG for higher current devices (like fans or fog lights)

-

Use charts to avoid overheating or voltage drop.

Consider Voltage Rating

-

Most car systems: 12V or 24V

-

Choose wires rated ≥ system voltage with margin (usually ≥60V rating for insulation)

Additional Considerations

-

Color coding: Helps with troubleshooting and standardization

-

Flexibility: Thin-wall wires (e.g., TXL, AVSS) are better for tight routing

-

Shielding: Needed for sensitive signal wires (e.g., CAN bus)

Summary Chart:

| Criterion | Choice |

|---|---|

| Temp Resistance | GPT (80°C), GXL/FLRY-B (125°C), SXL (150°C) |

| Insulation Type | PVC (standard), XLPE (high-temp), Teflon |

| Gauge (AWG/mm²) | Based on current & length |

| Standard | SAE (USA), DIN (Europe), JASO (Japan) |

| Application Location | TXL for tight spaces, AVSS for dashboards |

How to design and develop automotive wiring harnesses and match automotive wires

System Requirements Analysis

-

Define vehicle electrical architecture (12V, 24V, HV systems)

-

Identify all electronic components: ECUs, sensors, actuators, lights, infotainment, etc.

-

Gather current, voltage, and communication needs for each component

Circuit and Wiring Diagram Design

-

Create functional block diagrams, followed by schematic circuit diagrams

-

Include:

-

Power supply routing

-

Grounding points

-

Signal paths (e.g., CAN, LIN, Ethernet)

-

Fuse and relay locations

-

Use ECAD software like Zuken E3.series, Mentor Capital, or CATIA Electrical.

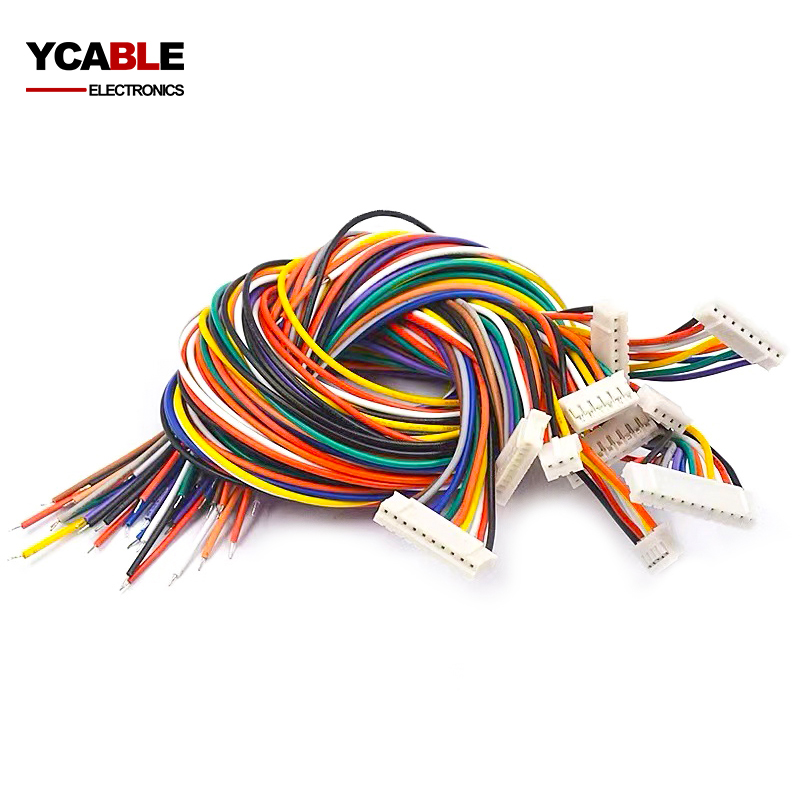

Wire Selection and Matching

Select wire type for each circuit based on:

| Parameter | Wire Choice |

|---|---|

| Current Load | Use AWG/mm² charts to match amperage with cross-section |

| Temperature Zone | TXL, GXL, FLRY-B for engine bay; AVSS/GPT for cabin |

| Standard | SAE (US), DIN (Europe), JASO (Japan) |

| Flexibility | AVSS, TXL for tight spaces |

| Shielding | Use shielded wires for EMI-sensitive lines (e.g., CAN) |

Also, select color codes and labeling schemes for easy service.

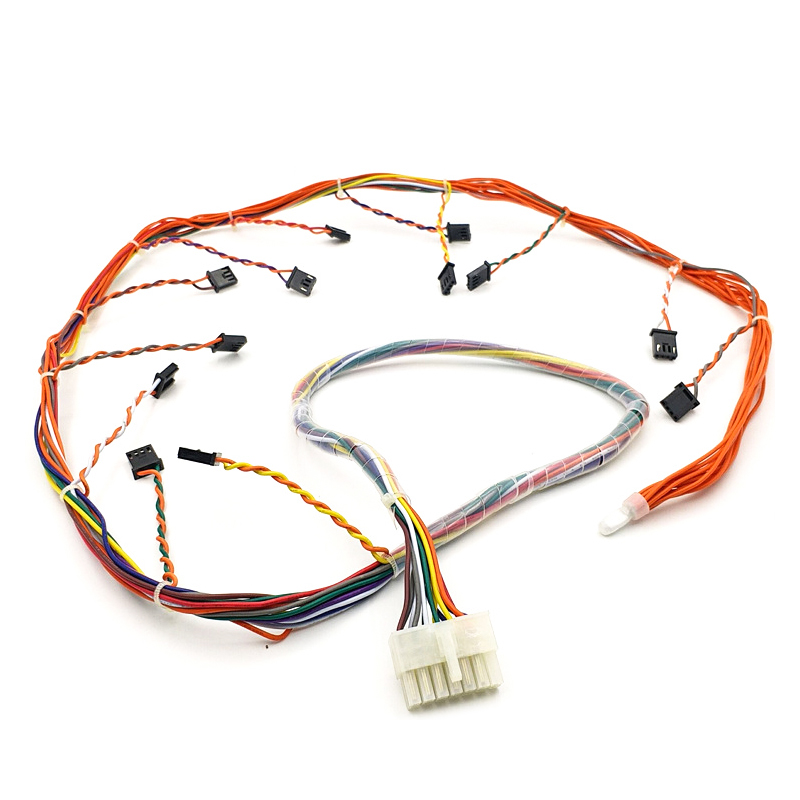

Harness Architecture Design

-

Design branch structure: main trunk + sub-branches

-

Determine:

-

Wire lengths

-

Connector types (sealed/unsealed, pin count)

-

Routing paths (based on vehicle 3D CAD layout)

-

-

Consider:

-

Bend radius

-

Mounting clips

-

Protection (tapes, sleeves, convoluted tubes)

-

Use 3D harness design tools integrated with vehicle CAD (e.g., CATIA Harness, Siemens NX).

Prototyping and Testing

-

Build a prototype using real components

-

Conduct tests:

-

Electrical: continuity, insulation resistance, voltage drop

-

Mechanical: vibration, abrasion, connector fit

-

Environmental: temperature cycling, fluid exposure, corrosion

-

Manufacturing Preparation

-

Prepare bill of materials (BOM), wiring tables, and cutting lists

-

Use automated machines for wire cutting, stripping, crimping

-

Document work instructions for assembly and QC

Final Validation and Compliance

-

Perform system integration in the vehicle

-

Validate against standards: ISO 6722, LV 112, SAE J1939, etc.

-

Ensure compliance with OEM-specific requirements (VW, Toyota, etc.)

Requirements → Schematics → Wire Selection → 3D Routing → Prototype → Test → Manufacture