Custom Heating belts Manufacturer In China

Heating belts, also known as electrical heating tapes or trace heating systems, are essential thermal management solutions widely used across industrial and commercial applications. These flexible heating devices function by converting electrical energy into heat through resistive elements, providing precise temperature control for various equipment and piping systems. The primary purpose of heating belts includes preventing fluid freezing, maintaining process temperatures, and ensuring operational efficiency in cold environments.

Our company specializes in manufacturing three main categories of heating belts tailored for specific applications: compressor heating belts, cold air blower duct heating belts, and drain pipe heating belts. Each type is engineered with distinct thermal characteristics to address unique operational challenges. Notably, we offer customized solutions to meet specialized requirements, adapting parameters such as power density, length, and insulation materials to match specific project needs.

How to correctly install the heating belt

The correct installation of heating belts is critical for both performance and safety. Proper connection methods involve:

Surface Preparation

- Clean the target surface thoroughly to remove dust, oil, or moisture using isopropyl alcohol or a degreaser.

- For metallic surfaces, apply a thin layer of thermal paste to enhance heat transfer efficiency.

Heating Belt Attachment

- Use manufacturer-provided aluminum tape or stainless steel clamps to secure the belt, ensuring full contact without kinks.

- Maintain a minimum bend radius of 3 times the belt's thickness to prevent damage to internal conductors.

Electrical Connections

- Connect the power supply to the designated terminals using crimped connectors with heat-shrink tubing for insulation.

- For parallel circuits, employ a Y-splitter rated for the total wattage to distribute power evenly.

Insulation & Protection

- Wrap the installed belt with fiberglass insulation tape, followed by a waterproof outer jacket for outdoor applications.

- Ensure all connections are enclosed in explosion-proof junction boxes for hazardous areas.

Testing & Verification

- Perform a continuity test (resistance within 10% of specifications) before powering on.

- Use a thermal imaging camera to verify uniform heat distribution after initial operation.

Safety Considerations

- Never cross or overlap heating belts to prevent localized overheating.

- Ground the system with a dedicated earth wire (resistance <4Ω).

- Install GFCI protection for circuits operating in wet environments. Selecting the appropriate power rating for heating belts is a critical step that directly impacts system efficiency and safety.

Our company specializes in manufacturing three distinct types of heating belts, each designed for specific industrial applications:

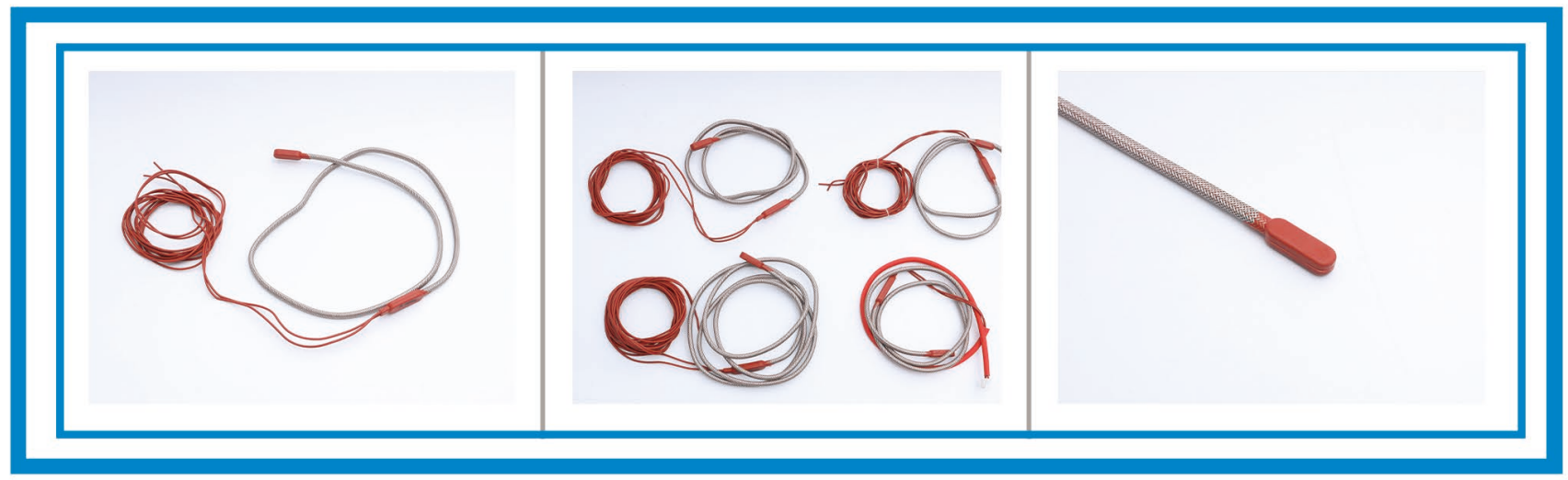

Compressor Heating Belts

Engineered to maintain optimal operating temperatures for air compressors, these belts prevent lubricant viscosity changes and condensation buildup in cold environments. Made from flexible silicone-rubber composites with embedded nickel-chromium alloy wires, they offer uniform heat distribution (typically 5-15W/ft) and withstand vibration stresses common in compressor installations.

| Voltage/V | Power/W | Width/mm | Length/mm |

| 24V—400V | 25 | 14MM 15MM | 500 |

| 50 | 1000 | ||

| 100 | 2000 | ||

| 150 | 3000 | ||

| 200 | 4000 | ||

| 250 | 5000 | ||

| 300 | 6000 | ||

| 35 | 500 | ||

| 24V—400V | 70 | 20MM 25MM 30MM 50MM | 1000 |

| 140 | 2000 | ||

| 210 | 3000 | ||

| 280 | 4000 | ||

| 350 | 5000 | ||

| 420 | 6000 | ||

| 560 | 8000 | ||

| 700 | 10000 | ||

| Note: | Other special specifications such as samples or drawings can be produced | ||

Cold Air Blower Duct Heating Belts

Designed for HVAC systems, these flat heating tapes adhere to duct surfaces to prevent ice formation and maintain airflow efficiency. Constructed with fiberglass-reinforced PTFE insulation, they operate at moderate temperatures (20-30W/ft) with built-in thermal cutoffs for safety in confined spaces.

| width | Size of the air duct of the air cooler | Specifications |

| 30MM 50MM | 400/4# | 220V 170W1270MM |

| 450/4.5# | 220V 200W 1420MM | |

| 500/5# | 220V 220W1590MM | |

| 550/5.5# | 220V 250W 1750MM | |

| 600/6# | 220V 260W1910MM | |

| 630/6.3# | 220V 270W 2000MM | |

| 650/6.5# | 220V 270W 2060MM | |

| 700/7# | 220V 280W 2220MM | |

| 800/8# | 220V 300W 2520MM | |

| Note: | Other special specifications can be customized for production based on drawings or samples provided | |

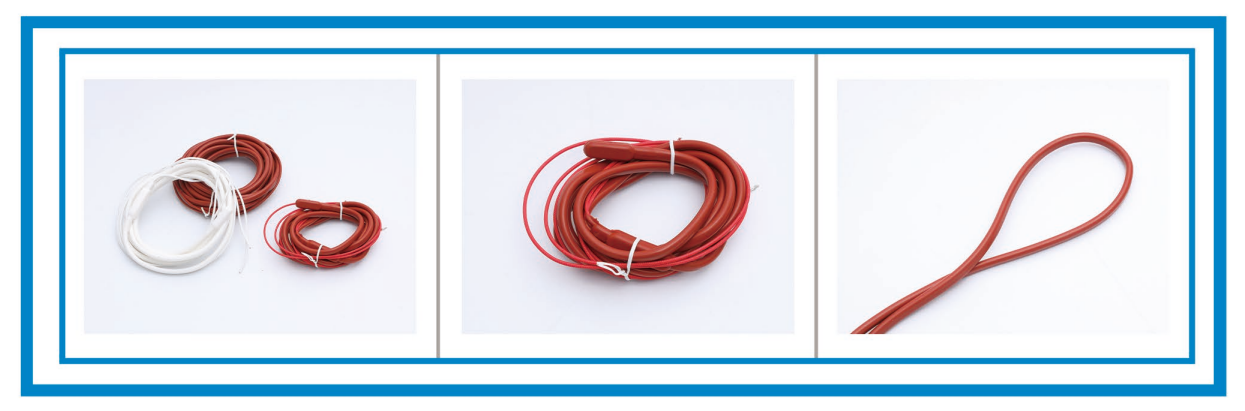

Drain Pipe Heating Belts

Used for freeze protection in plumbing systems, these self-regulating belts automatically adjust output based on ambient temperature. Incorporating conductive polymer cores, they provide burst protection (40-60W/ft) and are waterproof-rated for outdoor drain applications.

Customization Capabilities

Beyond standard models, we tailor heating belts to meet unique requirements:

Power density adjustments (±10% tolerance)

Length customization (up to 300ft per circuit)

Specialized insulation materials (e.g., fluoropolymer for chemical resistance)

Integrated temperature sensors for smart control systems

All products undergo 100% insulation resistance testing (≥50MΩ) and comply with IEC/UL standards for electrical safety.